Structural reinforcements for sports equipment

Sports equipment that is designed to withstand heavy loads and that has to retain its functions with a long durability requires structural reinforcement.

Tensile and flexural strength

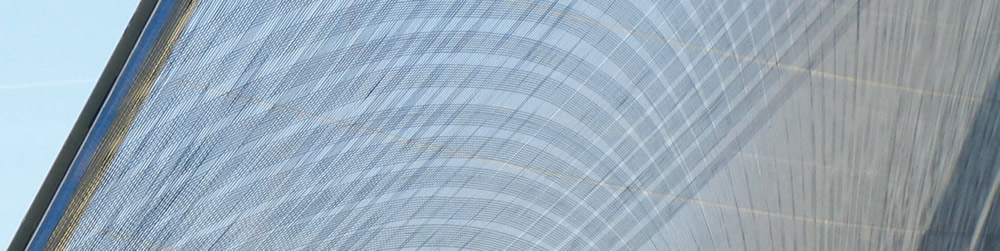

A well-dosed and controlled elasticity / deformability is essential for almost every piece of sports equipment. Whether it’s a ski, a sail, a tennis racket, the hull of a sailing boat or a surfboard: These structures have to absorb acting forces with a defined flexibility. The bouncing capacity and torsional / rotational stiffness has to be so high that the sports equipment neither breaks nor tears.

Vibration damping

The damping of vibrations is another important criterion for product quality, test results and sales success. Especially with rackets, this is one of the most sought after features.

Tearing strength and minimum weight

Sails, parachutes and paragliders have to meet the combination of tensile forces and safety requirements.

Sails, parachutes and paragliders have to meet the combination of tensile forces and safety requirements.

Their most important demands are tensile strength and minimal weight.

Engineers who look for such reinforcements for their constructions should include laid scrims within their considerations.

Laid scrims are suitable for:

- Skis

- Snowboards

- Tennis rackets

- Table tennis rackets / paddles

- Badminton rackets

- Squash rackets

- Surfboards

- Hulls of boats / yachts

- Sails for boats / yachts

- Surfing sails

- Kite-surfing sails

- Kite-boards

- Parachutes

- Hang gliders / paragliders

- Sailplanes

- Longbows

- Crossbows

- Hockey sticks

- Ice hockey sticks

The solution: Laid Scrims

Threaded fabrics are lightweight structures made of yarns / technical textiles. They combine exactly the features that define good sports equipment:

- Perfect for bouncing and torsional / rotational motions

- Extremely low weight

- Depending on the material: Extremely tearing proof

- Vibration dampening

- Dimensionall stabilizing

- Durable

- Cost efficient

Addes value by design and function

In most cases laid scrims are processed as an invisible layer within a sandwich construction, e.g. as a carbon layer within table tennis rackets.

Beyond their functionality, laid scrims offer you another valuable marketing opportunity:

Emphasize and visualize the added value of your hightech products!

Underneath transparent surfaces, scrims offer you interesting design options. Depending on the thickness, density and angle of the threads, you can make your products look even more filigree and / or stable.

Just on example: When consumers in a retail store compare different ski models, the mentioned design options are not the only competitive advantage. In the sales pitch, sports retailers can convincingly convey the main advantages of carving skis with laid scrims: reducing weight and improving the ability to spin. For ski pros and ambitious hobby athletes these are the strong arguments to prefer your products.

The ski manufacturer Fischer Sports perfectly implemented this sales and marketing approach for their high quality ski collection “Brilliant Pro” and “RC One Multiflex“, with a fitting marketing slogan “First Class and High Performance”:

What are laid scrims?

Laid scrims are lightweight structures made of yarns /technical textiles that differ significantly from ordinary fabrics:

- The threads don’t lie loosely upon and underneath each other. With a „binder“ they are glued permanently at their contact points.

- Threads run diagonally / multi-axial in 6 to 10 directions. Thus they absorb working forces significantly more effective.

- They are more flexible and simultaneously more stable.

- Their higher structural tearing strength allows wider meshes and a significantly lower weight per unit area.

- You can combine various options of materials, taking benefit of their specific characteristics.

- The threads of the scrim can be equipped with a multitude of impregnations to support the specific purposes of the final product.

For more information about BAFA®-laid scrims click here.

Our BAFA®-laid scrims are also used as production aids, for example in kite boards. The manufacturers use them in a lightweight, self-adhesive PES layer.

Suitability for automated production processes

Every second in production processes costs money. With BAFA®-laid scrims manufacturers save time in packaging. The processing of our scrims is usually done as an intermediate layer of sandwich constructions – where they also work stabilizing against the shifting of layers. You have 3 options to process them:

- As a layer within multi-layer products

- Gluing on contact surfaces (e.g. body panels)

- As an element of double-faced adhesive tapes

BAFATEX supplies laid scrims coiled in the widths you need. On request: Just-in-time. With their excellent cuttability and punchability they enable a high construcional quality and a high processing speed. Thus they are suitable for manual workmanship as well as for automated punching production lines.

Material options

Depending in which characteristics your product shall have we offer you laid scrims of these materials:

- Polyester

- Polyamid

- Viscose

- Aramid

- Glass fibre

- Carbon fibre

- Kevlar

- Bekitex

- Twaron

- Nomex

- Technora

- Steel filament mixed yarns

- Jute

- Cotton

- Flax

- Sisal

- more materials on request

The most commonly used materials to reinforce sports rackets are glass fibre and carbon. Both impress with their long durability under heavy load fluctuations.

The typical specification e.g. for a ski and snowboard: Carbon longitudinal threads in a BAFA-laid scrim 100/20 of 1100 dtex PES, black, combined with 1210 dtex Twaron.

Technical data

Please take a look at the data about tenacity, breaking load and elongation of:

Individual configuration

You can meet your demands and reinforce your products by altering multiple variables:

- Material, combination of materials and their characteristics (e.g. soft, hard, heat-sealable, waterproof, flame retardant)

- Thickness of the threads

- Width of the mesh

- Elongation (1,7 – 23%)

- Breaking load (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Angles (and hence force transmission) of crossing threads

- Colors

- Impregnators (Prepregs)

Know-how and consulting

Based on our experience of decades and our technical expertise we would be pleased to consult you about the range of characteristics and processing technologies of our scrims.

As a matter of course we are certified by DIN ISO 9002 (since 1994) to assure a permanent and high quality of our products.

Technical Literature: Reinforcement of composite materials with nonwovens

As technical literature for engineers we recommend:

“Composite Technology: Prepregs and Monolithic Part Fabrication Technologies” by Hauke Lengsfeld, Felipe Wolff-Fabris, Johannes Kraemer, Javier Lacalle and Volker Altstaedt, published by the Carl Hanser elibrary. You can find the list of contents and extracts here.

“Composite Materials: Processing and technology: Advancements in Prepreg processing & technology” by Muhammad M. Ali Rafique, published by Lambert Academic Publishing.

“Advances in Technical Nonwovens (Woodhead Publishing Series in Textiles)” by George Kellie

Lightweight Composite Structures in Transport: Design, Manufacturing, Analysis and Performance by James Njuguna

Ski images: Special thanks to Fischer Sports for the permission to publish them!