Within common fabrics all threads run on parallel axes.

The threads all cross each other loosely in an angle of 90 degrees. Never more than 2 threads cross each other at 1 point.

Forces work 4-directional.

Within a classic BAFA® laid scrim the parallel threads run on 3 axes. The crossing angles are customizable. Up to 3 threads cross each other at 1 point that is glued.

Forces work 6-directional.

The results are a higher dimensional stability, a lower elongation and a higher breaking strength – at a lower weight. This is what makes this technology so suitable for lightweight constructions.

For heavy duty products these characteristics have to be converted even more extremely.

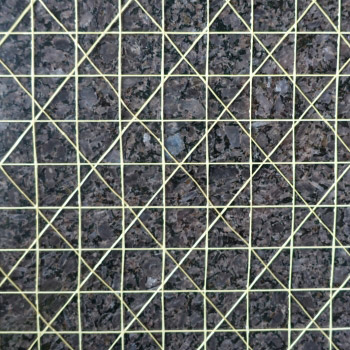

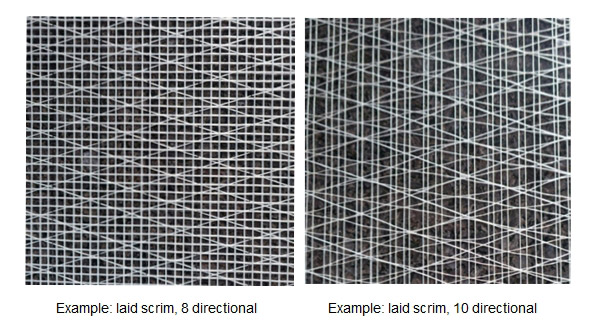

We convert our customer’s requirements for these special constructions of reinforcements by 8- or 10-directional BAFA® laid scrims. So on 4 or 5 axes up to 4 respectively 5 threads cross each other at 1 point – being glued together.

Range of Applications

8- and 10-directional BAFA® laid scrims are used in heavy duty products such as highly charged sports equipment (skis, sailing yachts) and highly stressed floorings (tartan tracks, indoor floors).

Advantages:

- Extreme dimensional stability

- Very low elongation

- High tenacity, also in connection with fleece

- Water permeability for outdoor use with the ability of percolation (e.g. tartan tracks)