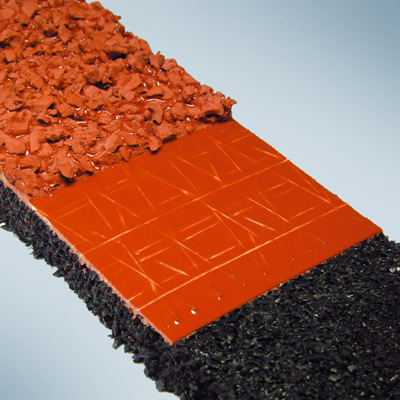

Tartan tracks are the technically most demanding sports floorings.

They have to keep their characteristics under heavy-duty and for any kind of weather. Neither very high or very low temperatures, ultraviolet rays or humidity may cause considerable effects on their most important features: Grip and elasticity.

BAFA®-laid scrims help to compensate force effects within the layers of your products. They are integrated within in situ– as well as hybrid coatings, between the polyurethane / rubber granulate material (SBR) and the EPDM surface layer.

Characteristics for the reinforcement of your products

BAFA®-laid scrims enhance your products with qualities that meet your customers demands of upmarket floorings:

- Stable and simultaneously flexible

- High tensile, bending and bending tensile strength

- Durability, reduction of wear-outs

- More elastic and twistable than rectangular fabrics

- Combinable characteristics of up to 5 materials (10-directional yarns)

- Permeable to gases and liquids

- Depending on the material: waterproof, suitable for wet-rooms

- If required (depending on the material): consistent against acids and alkalis

- With its permeable structure applicable for underfloor heatings, complying ISO 8302

- Applicable for flame-retardant materials and finishings according to EN 13501-1

- Applicable for DIN EN 1815:2016-12 according to electrostatic charge of „elastic and textile floorings”

- Alternative to heavy coatings, foam layers, fleece and knitted fabrics

- Very attractive cost-benefit ratio

Differences between laid scrims and fabrics

Laid Scrims are structures made of yarns / technical textiles, that differ significantly from conventional fabrics:

- The threads run diagonally / multiaxial in at least 6 (up to 10) directions. This they compensate acting forces in a much higher degree.

- The threads don’t lie loose upon and underneath each other. They are solidly glued at their crossing points with a variety of „binders“ for custom purposes.

- They have a higher stability and simultaneously a higher flexibility.

- Their higher structural tearing strength allows wider meshes and a significantly lower weight per unit area.

- Up to 5 materials can be combined with its specific characteristics.

- The threads can be finished with a variety of impregnations that support specific purposes.

Additional value by quality and profitability

BAFA®-laid scrims give you the opportunity to create an additional value by a higher product quality.

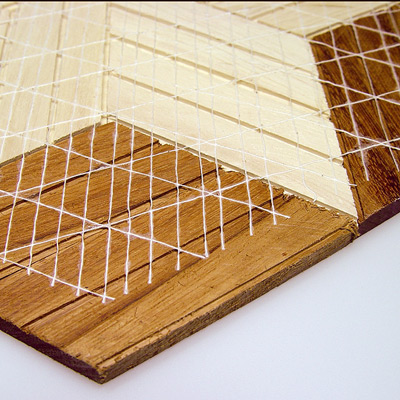

(Image left / above: Application as a textile back finishing for a premium parquet quality)

With this additional value your sales representatives can reason a higher price than products of competitors.

The results are higher revenues, higher margins, more satisfied customers and a strengthened brand.

Material: Options

Depending on which characteristics your product shall have we offer you laid scrims of these materials:

- Jute

- Cotton

- Flax

- Sisal

- Polyester

- Polyamide

- Viscose

- Aramid

- Glass fibre

- Carbon fibre

- Kevlar

- Bekitex

- Twaron

- Nomex

- Technora

- Steel filament mixed yarns

- more materials on request

Flexible, stable, lightweight, customizable

You can reinforce your products by customizing BAFA®-laid scrims to your demands:

- Materials, combination of materials and their characteristics (e.g. soft, hard, waterproof, heat-sealable, flame-retardant)

- Angles (and hence force transmission) of crossing threads

- Width of the mesh

- Thickness of the threads

- Breaking load (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Elongation (1,7 – 23%)

- Impregnators (Prepregs)

- Colors

Automated production processes and artisanal handling

BAFATEX supplies laid scrims in coiled widths between 100 and 2.700mm. With their excellent cuttability and punchability they enable a high build quality and a high processing speed. Besides the processing as a glued bottom layer finishing the integration in intermediate layers (especially for highly elastic floors) is a common way to use our pre-products.

With their excellent cuttability and punchability BAFA®-laid scrims are perfectly applicable for cutting production lines. Moreover they facilitate the artisanal / manual handling for tilers, carpet fitters and other craftsmen on site.

Prefabrication is exceedingly favourable for laying mosaic floors of stone, wood / parquet and glass. Instead of laying mosaics like complicated puzzles on site tediously with the prerequisite of the capabilities of an artist you can make it faster and cheaper. With prefabricated tile-like elements that are fixed with BAFA®-laid scrims as a layer, average craftsmen on site will appreciate that they just have to assemble more simple elements.

Know how and consultancy

Based on our technical expertise and our experience of decades we would be pleased to serve you with consultancy about the range of characteristics as well as about the options of processing technologies of our scrims.

To assure a consistent and high quality of our products we are certified by DIN ISO 9002 since 1994.