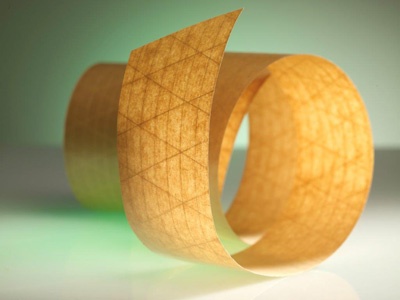

BAFATEX supplies manufacturers of these packagings (and of packaging aids such as adhesive tapes, see image on the left) with „laid scrims“ to reinforce their products.

Laid scrims are structures of yarns / technical textiles.

They differ considerably from conventional fabrics:

- The threads run diagonally / multiaxial in 6 directions. Thus they absorb working forces significantly more effective.

- The threads don’t lie loose one above the other. At their points of contact they are solidly glued by a „binder“.

- They are more stable and simultaneously more flexible.

- Their higher structural tearing strength allows wider meshes and a considerably lower weight per unit area.

- Various options of materials can be combined, taking benefit of their specific characteristics.

- The threads can be equipped with a multitude of impregnations that support the specific purposes of the final product.

Reinforcements of Packaging Products for Transport and Sales

BAFA®-laid scrims are most notably used to reinforce:

- Closed paper bags

- Paper bags with viewing panels (e.g. potato bags)

- Transport boxes / shipping cartons, moving boxes

- Envelopes

- Bubble Wraps / air cushion foils

- Highly transparent foils

- Anticorrosive coating papers

Added Value by Quality and Profitability

BAFA®-laid scrims offer you the opportunity to add value to your products by increasing its quality. Thus your sales department can give your customers reasons for higher prices and higher profits.

Example: Discounters sell corrugated boxes, 600x400x400mm, C-wave carton (German explanation), payload up to 40kg, for a price of 1,59 € incl. VAT. Such prices cannot include considerable margins for manufacturers (especially when the manufacturing is located in high-cost regions like Western Europe). Retailers and DIY markets react to this by reducing the quality of their home brand products and use a thinner layer thickness (e.g. E-wave instead of C-wave). The results are boxes with poor quality that tend to rip quickly. Customers get angry and disappointed. The home brand is damaged.

With BAFA®–laid scrims you increase the tearing strength and durabilty of your packaging products. Instead of using expensive, humidity-resistant paper types or coatings / laminations, you can use a cheaper type and reinforce it with laid scrims.

Bottom line: Higher revenues, higher profits, more satisfied customers and a strengthened home brand.

Materials for Logistics, Beverages and Food

Of course the use of materials depends on its purpose.

For food and beverage legal regulations are legitimately and particularly strict.

The basis for packagings made of paper, paperboard and carton with contact to food / beverage is the EU Regulation (EC) No 1935/2004.

Laid Scrims made of the yarn materials cotton, jute, flax, polyester und polyamide are particularly suitable for the contact with food. For premium protection or precious goods we offer yarns made of glass fibre, Kevlar and carbon.

Flexible, stable, lightweight, customizable

You can reinforce your products by customizing several variables of BAFA®-laid scrims to meet your demands:

- Materials, combination of materials and their characteristics (e.g. soft, hard, waterproof, wash and dry cleaning resistant, heat-sealable, flame-retardant)

- Thickness of the threads

- Width of the mesh

- Elongation (1,7 – 23%)

- Breaking load (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Angles (and hence force transmission) of crossing threads

- Colors

- Impregnators (Prepregs)

Suitability for Automated Production Processes

BAFATEX supplies laid scrims in coiled widths – on request just-in-time. With their excellent cuttability and punchability they enable a high build quality and a high processing speed. Many manufacturers bond the scrims on the interior surfaces, as the outsides are designed for marketing purposes (smooth, shiny surfaces, with prints).

Within multi-layer products (e.g. corrugated cardboard boxes) the laid scrims are glued on the inside of the smooth paper layer with contact to the wave carton. Alternatively or additionally they can provide fastening flaps with a higher tearing strength. With their excellent cuttability and punchability they are perfectly applicable for cutting production lines.

Sustainable, biodegradable reinforcements

BAFATEX is committed to the transformation of industry towards sustainable production. We supply manufacturers with ecologically sustainable laid scrims made of renewable raw materials / natural yarns.

This added value enables you to win new customers, avoid plastic waste and more easily meet the requirements of the packaging laws.

(read more: Examples for the packaging industry)

Know How and Consulting

As a matter of course we are certified by DIN ISO 9002 (since 1994) to assure a uniform and high quality of our products.

Based on our experience of decades and our technical expertise we would be pleased to consult you about the range of characteristics and processing technologies of our scrims.

Technical Literature

Diana Twede, Susan E.M. Selke: Cartons, Crates and Corrugated Board: Handbook of Paper and Wood Packaging Technology

Joseph F. Hanlon, Robert J. Kelsey, Hallie Forcinio: Handbook of Package Engineering

Walter Soroka: Fundamentals of Packaging Technology