Nonwovens: Reinforcement of tear resistance with BAFA® laid scrims

We supply manufacturers of nonwovens with laid scrims to reinforce their products.

Laid scrims provide your product with structural reinforcement (increase in tensile strength). If required, a stainless steel fibre adds antistatic properties to your nonwoven product.

You can integrate our yarn scrims into any type of nonwoven fabric, either as an intermediate layer or surface layer:

- Chemically bonded nonwovens

- Thermally bonded nonwovens

- Needlepunched nonwovens

- Cross-layer nonwovens

- Confused- / isotropic fleeces

- Oriented / anisotropic fleeces

- Water-jet fleeces

- Wet laid nonwovens

- Spunbonded nonwovens

- Melt spunbonded nonwovens (meltblown)

- Staple fibre nonwovens

- Multilayer composites

Of course, to maximise the sustainability of your products, we also offer scrims made of renewable raw materials / natural fibres.

Tear resistance and minimal weight

In the case of nonwovens and filters, the combination of tensile forces and safety requirements means that tensile strength is particularly important – with minimum weight. Especially with basis weights of less than 100 g / m², any kind of reinforcement must also be lightweight.

In the case of nonwovens and filters, the combination of tensile forces and safety requirements means that tensile strength is particularly important – with minimum weight. Especially with basis weights of less than 100 g / m², any kind of reinforcement must also be lightweight.

Engineers who are looking for such reinforcements for their designs should include scrims in their considerations.

Scrims are suitable for reinforcing all product categories of nonwovens, such as:

- Building products such as insulating materials (thermal insulation, sound insulation), roofing membranes, waterproofing membranes, liquid plastic sealants or joint reinforcement strips

- Filter

- Automotive (thermal insulation, sound insulation, vibration damping, seat padding)

- Textiles / Clothing

- Gardening and landscaping products such as protective fleece, mulch fleece, irrigation fleece or seed rearing fleece

- Upholstered furniture, mattress elements (spring core cover) with special focus on tear resistance and abrasion

- Home Textiles

- Floor coverings, footfall sound insulation

- Transport packaging

- Food Packaging

- Sports equipment

- Medical Technology

- Clinical and hygiene products

- Sewer rehabilitation

- Laminating and laminating applications

Antistatic properties

Electrostatic charges, which are caused, for example, by the friction of nonwovens against surfaces or particles of an air flow, must be dissipated by earthing for certain types of use (for example within potentially explosive atmospheres).

As integrated metal scrim you can connect a BAFA®-laid scrim for protective earthing / functional earthing with an earthing lug or an earthing bolt.

What are laid scrims?

Laid scrims are lightweight structures made of yarns / technical textiles that differ significantly from ordinary fabrics:

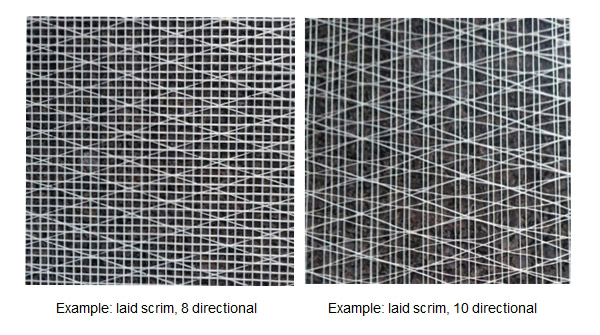

- Threads run diagonally / multi-axial in 6 to 10 directions. Thus they absorb working forces significantly more effective.

- The threads don’t lie loosely upon and underneath each other. With a „binder“ they are glued permanently at their contact points.

- They are more flexible and simultaneously more stable.

- Their higher structural tearing strength allows wider meshes and a significantly lower weight per unit area.

- You can combine various options of materials, taking benefit of their specific characteristics.

- The threads of the scrim can be equipped with a multitude of impregnations to support the specific purposes of the final product.

For more information about BAFA®-laid scrims click here.

Threaded scrims combine exactly the properties that make high-quality or technically sophisticated nonwoven products:

- Extremely light

- Depending on the material extremely tear-resistant / flexible, electrically conductive

- Moisture resistant

- Temperature resistant up to the upper limit of filters and fleeces

- Dimensionally stabilizing

- Durable

- Cost-effective

Added value through design and function

In most cases, scrims are processed invisibly as an intermediate layer in sandwich construction. However, this does not yet exploit its full potential. In addition to their functionality, laid scrims offer you another valuable option:

Emphasize and visualize the added value of your high-tech products!

Threaded scrims offer you interesting design options under transparent surfaces or as top layer. Depending on the thickness, density and angle of the threads, you can make your products look even more filigree and/or stable.

Processing, mechanical manufacturing processes

BAFATEX supplies laid scrims wound on rolls. They are designed for mechanical production processes and a high processing speed. BAFA®-laid scrims are characterised by good cutting and punching properties. This makes them suitable both for punching production lines and for manual use by craftsmen and private customers.

Individually customizable

You can reinforce your products with several variables and adapt them to your requirements:

- Material, combination of materials and their properties (e.g. soft, hard, heat sealable, waterproof, flame retardant)

- Impregnation / adhesive material

- Width of the mesh

- Breaking load (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Elongation at break (1,7 – 23% compared to e.g. 80-150% for unreinforced PVC adhesive tape, whereby a scrim has a definable elasticity not only due to its material, but also due to its structure / angle)

- Angles (and hence force transmission) of crossing threads

- Colors

- Impregnators (Prepregs)

Material options

Depending in which characteristics your product shall have we offer you laid scrims of these materials:

- Natural fibres: Jute, cotton and flax (more information)

- Man-made fibres (more information)

Your supplier with know-how and consulting

Based on our experience of decades and our technical expertise we would be pleased to consult you about the range of characteristics and processing technologies of our scrims.

As a matter of course we are certified by DIN ISO 9002 (since 1994) to assure a permanent and high quality of our products.