What are laid scrims?

Laid scrims are lightweight structures made of yarns / technical textiles that differ significantly from ordinary fabrics:

- Threads run diagonally / multi-axial in 6 to 10 directions. Thus they absorb working forces significantly more effective.

- The threads don’t lie loosely upon and underneath each other. With a „binder“ they are glued permanently at their contact points.

- They are more flexible and simultaneously more stable.

- Their higher structural tearing strength allows wider meshes and a significantly lower weight per unit area.

- You can combine various options of materials, taking benefit of their specific characteristics.

- The threads of the scrim can be equipped with a multitude of impregnations to support the specific purposes of the final product.

For more information about BAFA®-laid scrims click here.

Areas of application for adhesive tape with thread scrim

- Packaging (sealing of cardboard boxes, heavy objects, dangerous goods, etc., wet adhesive tape for sealing cardboard boxes)

- Metal industry (tool making, mould making, mechanical engineering)

- Wood processing industry (furniture industry, carpentry, kitchen construction, model making)

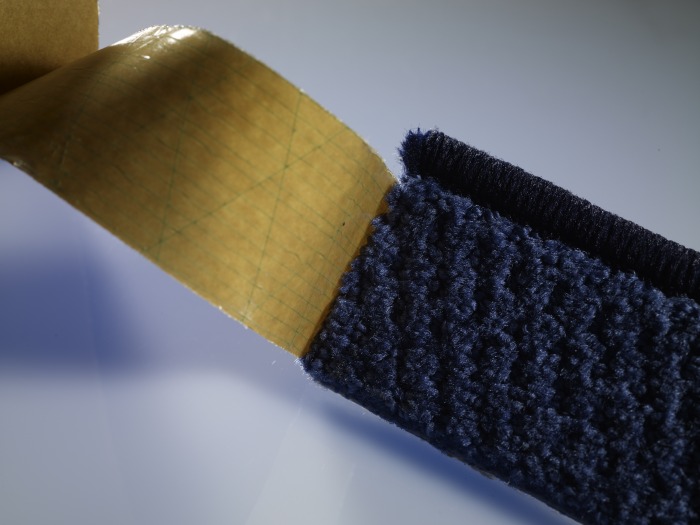

- Adhesive tape for skirting boards in the floor laying area (with BAFATEX scrims the adhesive has more grip, thus preventing the binder from running)

- Automotive industry (especially as double adhesive tape for assembly and fastening of foam parts)

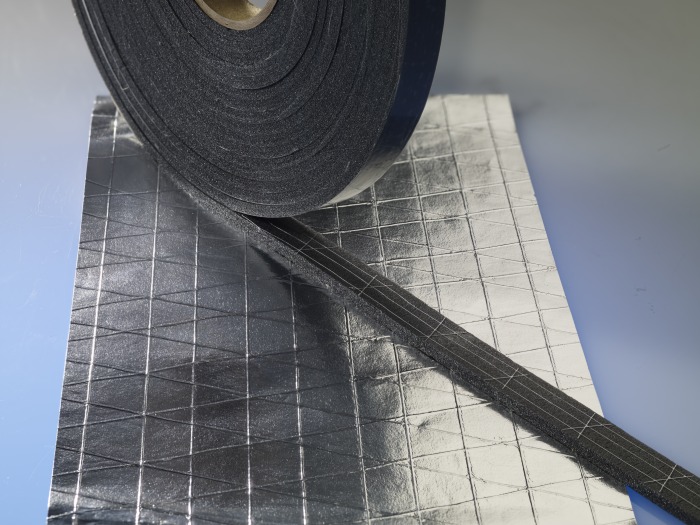

- Double-sided self-adhesive foam tape for insulation, sound insulation, spacers and sealing material for windows and doors.

- electrical trade

- plumbing trade

- handicraft

- jewellery craft

- painter’s craft

- construction industry

- food technology

- Chemical industry

- medical technology

- pipeline construction

- aircraft construction

- shipbuilding

Processing, mechanical manufacturing processes

BAFATEX supplies yarn scrims wound on rolls. They are designed for mechanical production processes and a high processing speed. BAFA®-laid scrims are characterised by good cutting and punching properties. This makes them suitable both for punching production lines and for manual use by craftsmen and private customers.

Individually customizable

You can reinforce your products with several variables and adapt them to your requirements:

- Material, combination of materials and their properties (e.g. soft, hard, heat sealable, waterproof, flame retardant)

- Impregnation / adhesive material

- Width of the mesh

- Breaking load (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Elongation at break (1,7 – 23% compared to e.g. 80-150% for unreinforced PVC adhesive tape, whereby a scrim has a definable elasticity not only due to its material, but also due to its structure / angle)

- Angles (and hence force transmission) of crossing threads

- Colors

- Impregnators (Prepregs)

Material options

Depending in which characteristics your product shall have we offer you laid scrims of these materials:

- Natural fibres: Jute, cotton and flax (more information)

- Man-made fibres (more information)

Your supplier with know-how and consulting

Based on our experience of decades and our technical expertise we would be pleased to consult you about the range of characteristics and processing technologies of our scrims.

As a matter of course we are certified by DIN ISO 9002 (since 1994) to assure a permanent and high quality of our products.