In contrast to manufacturers who produce any kind of technical textiles / woven fabrics we are committed to laid scrims.

From low to very high amounts we provide customers in Europe, North America and Asia with any quantity they need.

Whether you need 100 square meters for prototypes and research – or millions of square meters for mass production: Our production planning is as flexible as you need it.

We can process any material that is suitable for scrims. The list of materials you find below represents just the most common material groups.

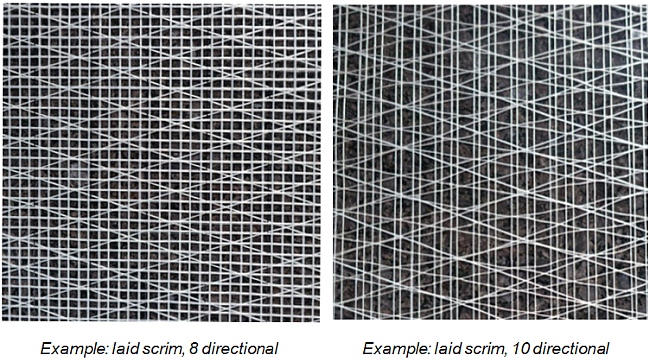

While woven fabrics and nets handle force effects only 4-direcional, regular scrims handle them 6-directional. BAFATEX® is probably the only supplier who is able to produce even 8-directional and 10-directional laid scrims for highest performance in lightweight construction.

Your partner from development to serial production

You are not sure which kind of carbon fibers you need? High tenacity fibers? High modulus? Intermediate modulus? High strain and tenacity fibers? How do they behave at certain temperatures, humidity or x-rays? Are aramid fibers a better solution for your product than carbon fibers? Is flax the insider tip that fits best? Did you know that certain polyethylene fibers are ten times stronger than steel?

We are your partner in developing solutions, not just products.

In your development and product optimization, we will counsel you with all our experience and expertise. If necessary, we will connect you with our network of yarn manufacturers and material research institutions. Their experts can provide you with the complete knowledge that is available.

Usually our customers either have an existing product they want to optimize or a rough idea about the characteristics of a lightweight reinforcement for their new products. The typical procedure:

- Calculations are the first step. Customers appreciate our online tool “product consultant” that enables engineers to see the results of different product configurations. By altering materials, material strengths, mesh widths, binders etc. you can see the layout, the breaking strength and elongations at break (based on statistical data given by the yarn manufacturers).

- The next step is to move from theory to hardware testing. In the development /prototype phase, we supply our customers with samples of scrims with different characteristics. Our huge sample stock offers you lots of options.

- For your first small batch series, we offer you customized scrims in low quantities, produced with your unique machine settings. They will be delivered in coiled widths to test their usage in your automated production lines.

- Finally we supply you with the scrims that fit your demand perfectly, in any quantity you need, just-in-time (and in dependence of storage shelf life) with attractive prices.

With our certified quality assurance you can rely on a production that meets your specifications permanently.

Range of Applications

Laid scrims are are allrounders when it comes to reinforce lightweight constructions, fleece, filters etc.

Some examples of applications:

- Building industry, e.g. to dampen and to prevent cracks

- Automotive industry, e.g. sound absorption elements

- Lightweight constructions like wind energy plants and aircraft industry

- Filters / non-wovens

- Packaging, especially reinforcements of paper packagings

- Floorings like carpets, sports tracks, tiles and mosaics of wood, glass and stone

- Home decorations, gift wrappings, interior architecture (e.g. illuminated glass fibers in concrete)

- Sports equipment like sails, boat hulls, rackets, skis, parachutes, surfboards

There is no limit to applications for our scrims: Prostheses, cable coatings, fuel tanks, tents, bulletproof vests, roofs, helmets, ship propellers, chainsaw protection, light weight armor, hoses, foils, archery bows, buoys, covers for fields or pools, balloons,…

Material options

Depending in which characteristics your product shall have we offer you laid scrims of these materials:

Natural fibres

- Jute

- Cotton

- Flax

- Sisal

Man-made fibres

- Polyester

- Polyamid

- Viscose

- Aramid

- Glass fibre

- Carbon fibre

- Kevlar

- Bekitex

- Twaron

- Nomex

- Technora

- Steel filament mixed yarns

- more materials: On request

Customization

You can customize the characteristics of BAFA®-laid scrims to your requirements by altering several variables:

- Materials (see above)

- Binder characteristics: soft or hard to handle, waterproof, wash and dry cleaning resistant, heat-sealable, flame-retardant

- Strength of the yarns

- Width of the mesh

- Elongation until point of break (1,7 – 23%)

- Breaking strength (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Combination of materials and their characteristics

- Angles (and hence force transmission) of crossing threads

- Colors

- Impregnators (Prepregs) and their characteristics (waterproof, flame retardant, etc.

BAFA®-scrims are designed with a structure that provides your product with characteristics your customers require from lightweight reinforcements or filters / fleece:

- Stability

- (Depending on the materials) higher elongation and resiliency than conventional fabrics

- (Depending on materials) high impact and abrasion resistance

- Special electrical and chemical properties

- Combinability of the characteristics of various materials

- Lower weight than fabrics

- air permeability

- waterproof, antistatic or flame retardant finishing (impregnation instead of coatings)

- vibration dampening

- Lower costs than most alternative solutions

And what can we do for you?

Are you looking for a scrim that can still work in intense heat? Or a scrim that is water resistant? Do you need a scrim that makes daily work easier? Or a scrim that optimises your production process? Would you like to have a scrim of decomposable natural fibres or a long lasting high-tech fibre? Or? Or?

Together we can develop a perfect scrim for your application.

We are pleased if you contact us. Together we will find the perfect solution for your products.